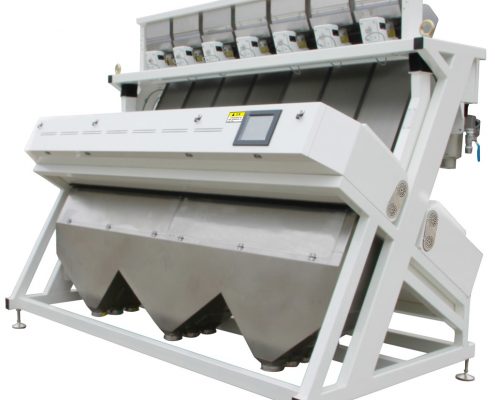

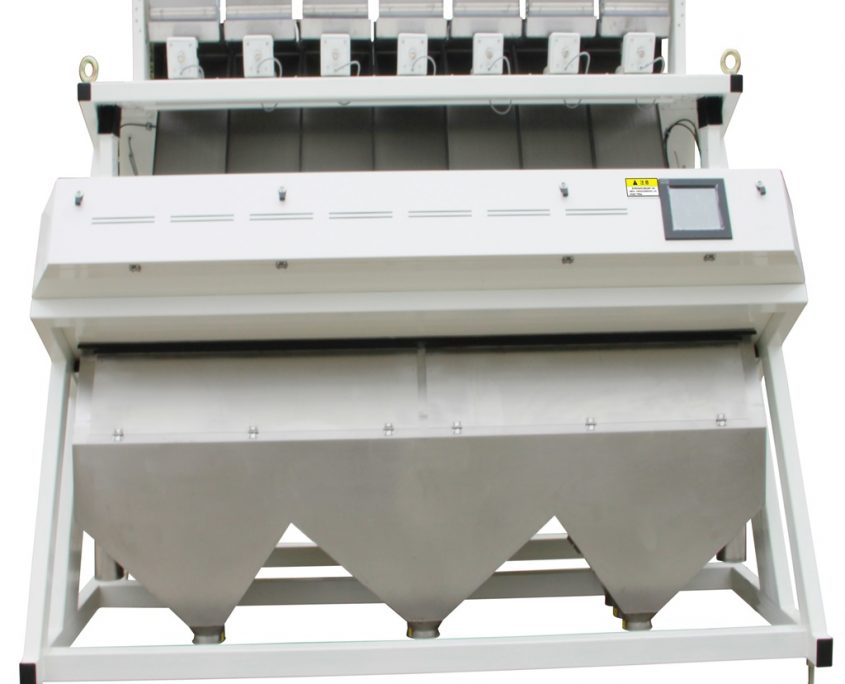

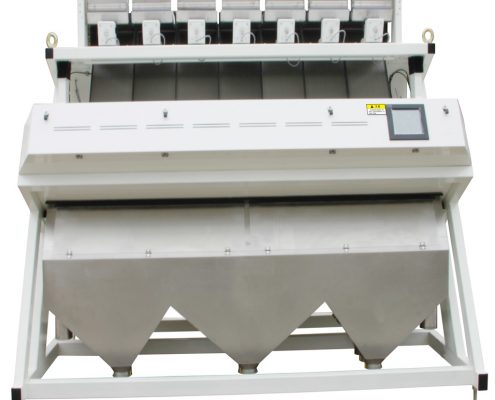

CCD Rice Optical Color Sorter RCSB7

CCD Rice Optical Color Sorter RCSB7 – Metak Color Sorting

Technology Data:

| Model | RCSB7 |

| Output(t/h) | 5-15 |

| Carryover (bad: good) | 15:1 |

| Accuracy (%) | 99.99% |

| Voltage (V/Hz) | 220/50 |

| Power (Kw) | 2-4.5 |

| Air pressure (Mpa) | 0.6-0.8 |

| Consumption (L/min) | <4500 |

| Weight (Kg) | 1600 |

| Dimensions (mm) | 2924*1624*2175 |

CCD Rice Optical Color Sorting Machine RCSB7 Features:

1, Unique-in-the-industry light different color selection mode is efficient for the high-end color selection of light beige, speckled or darkened rice. The first-time output compounding rate is over 1:1, and the second-time more than 15:1. (Bad: Good) Under this mode, the signal separation of belly-white and shallow yellow would be accomplished, selecting the yellow without any white, as is a pioneering technology in the industry.

2, Under the different-color mode, color-selection requirements of all kinds of grain can be achieved. The first-time output compounding rate is over 1:1, and the second-time more than 15:1. (Bad: Good)

3, Under the belly-white mode, color selection will be further optimized. For the belly-white, the first-time output compounding rate is above 1:1; and the second-time over 25:1. For full-white or full-yellow, the first-time output compounding rate is also above 1:1; and the second-time more than 30:1. With easy mode-shift function, unique 3-color convertible background board, all modes are free to shift in betweens by changing the automatic light sources, except for the reversed-selection mode which requires special light source.

4, Newly-optimized operating interface is quite user-friendly. The “one-button auto” and “project back-up” functions help to reset the original parameters when misconduct happens.

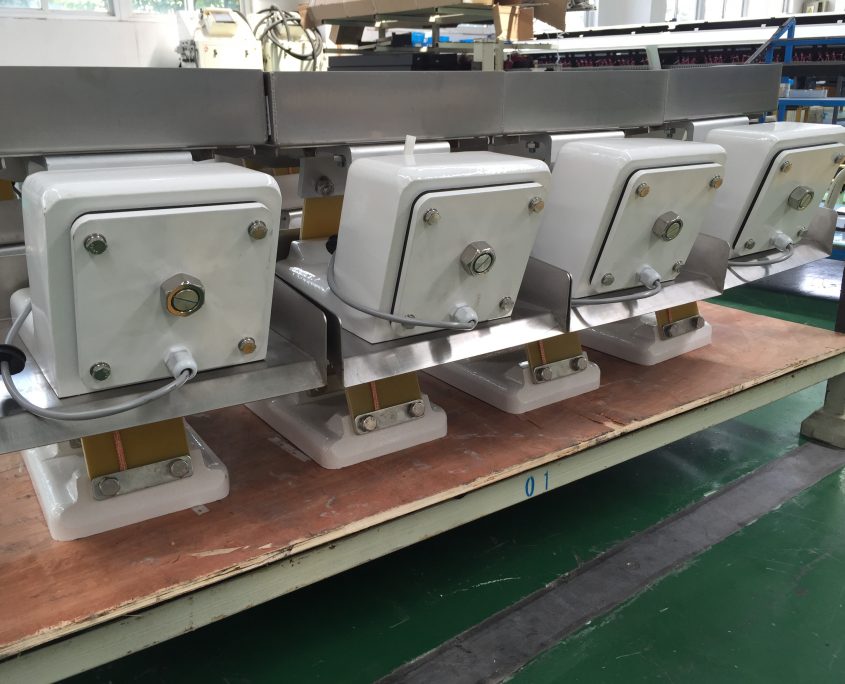

5, Newly-designed mechanical structure provides favorable stability and applicability. There are two output mode, the large-chute mode and separated small-chute mode. Each mode is equipped with reinforced chutes that greatly reduce the output compounding rate. Large chute is convenient for installation, while small chute allows the user to change into “3-time color selection” model according to customer requirements.

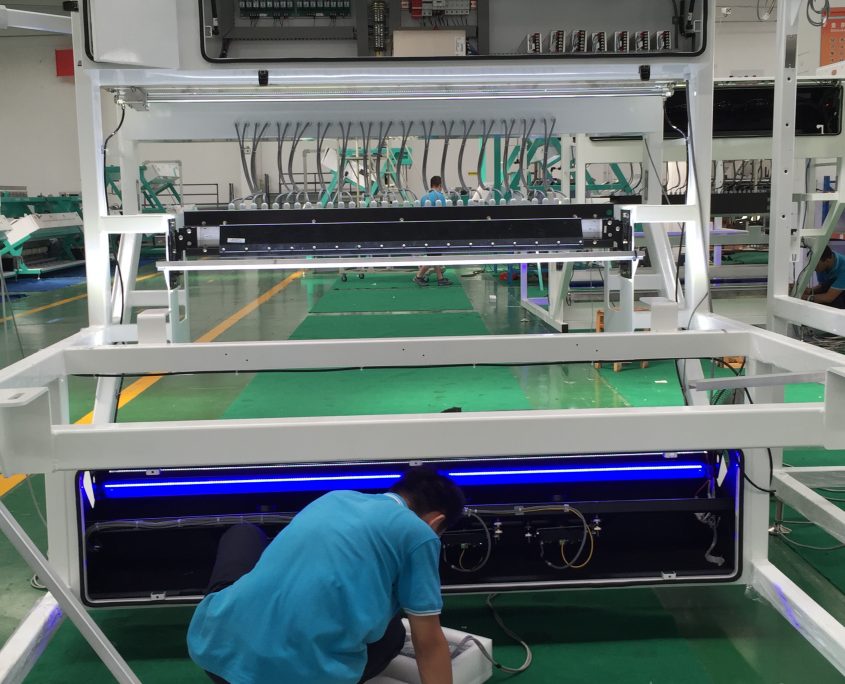

6, Innovative smart LED shadowless cold light system design can efficiently find out small spots, light yellow,belly-white,core-white,black pin-points, which makes identification and judgment much easier, sorting more accurate. The light source has long service life, high luminous efficiency and strong anti-interference stability, and no warm-up is needed.

7, Unique direct-spray nozzle has greatly eliminated the huffing resistance, reduced the air consumption, accelerated the response speed and made the operation more accurate and effective whist diminishing the output compounding rate.

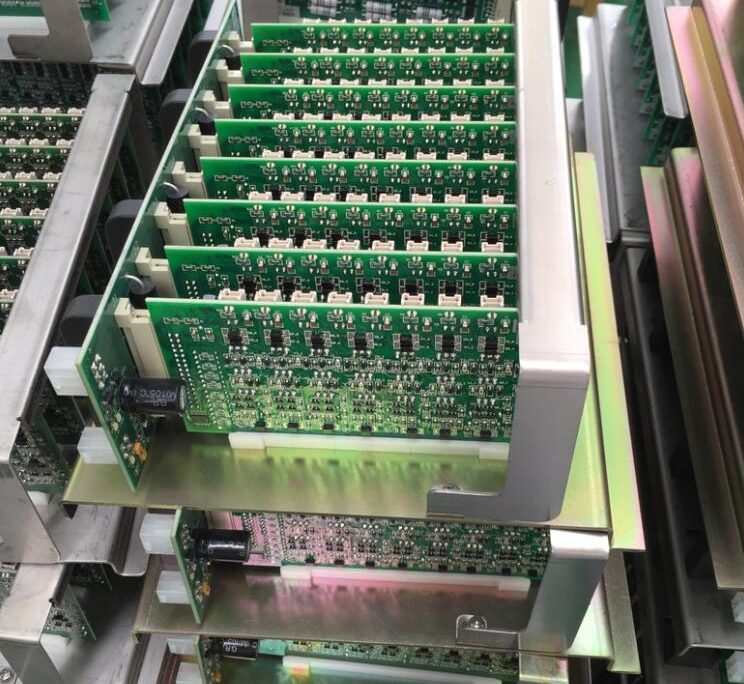

8, International cutting-edge industry special 5088 full-color high-speed line scan imaging sensor CCD, and special color sorting camreas tailored by top International suppliers,can precisely identity subtle spots of 0.04 mm², and meet high-end color sorting requirements of synchronous sorting and independent sorting for belly-white and core-white.

9, The rice small lesion, shallow yellow, white belly, white core, needle point such as black Leis, grain,aiming at provide more flexible separation combination scheme in the multiple modes of complex intelligent algorithm, color sorting accuracy higher, ratio of lower.

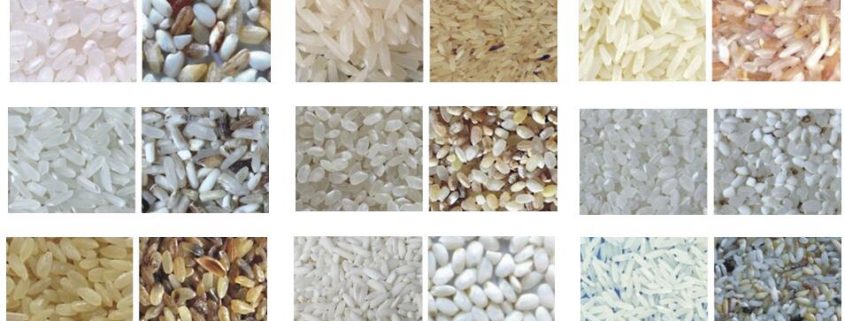

Example of Sorting:

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 20- 30 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation:

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

After Sales Services:

• With presence in a variety of countries, Metak is strongly committed to being close to the customer.

• Through cooperation with loyal and carefully evaluated and trained local employees and partners, Metak managed to provide fast, competent and rooted services in the context of customers.

• Application center in Hefei production base offer demo machines for tests and comparison.

• A strong central technical team in Hefei is supporting local channels with training, advice and technical support.

• Under normal working circumstances, Metak machines enjoy 1 year of full warranty and a lifelong warranty on the machine structure upon the date of purchase.

• Service line is available for emergency support.

• Metak products will be serviced and supported wherever customers are located.

• Through the global Metak network and from Metak technical experts, training on Metak machines is available worldwide.

Metak Rice Optical Sorting Machine Working Video

How does the Metak Rice Color Sorter Machine Work?

According to the different color selection of materials, detecting the colors of the granular materials that pass before them, and using mechanical or pneumatic ejection devices to divert the material whose colors do not fall within the acceptable range.

Suitable rice sorting and grading: All kinds of rice.

How Metak Rice Color Sorter Machine Can Help you?

Improving your profitability:

Highest quality production

Lowest product loss

Diverse products, any contaminant

Minimal product damage

Low operating costs – long term warranty

Optimum recovery rates

Enhancing your productivity:

Minimum operator skills

High uptime

Quick and easy installation

Maintenance from remote locations

For consistency in production

Effective in harshest environments

Get Your Solutions with Metak Rice Color Sorter Machine, Inquiry us NOW!